Wall mount type ultrasonic flow meter installation requirements

The state of the pipeline for measuring the flow will greatly affect the measurement accuracy, the detector installation location should be selected in a place that meets the following conditions:

1. It must be ensured that the straight pipe section where the probe is installed is: 10D on the upstream side(D is the pipe diameter), 5D or more on the downstream side, and there must be no factors that disturb the fluid(such as pumps,valves, throttles, etc.) in the 30D on the upstream side. And try to avoid the unevenness and welding position of the pipeline under test.

2. The pipeline is always full of liquid, and the fluid should not contain bubbles or other foreign objects. For horizontal pipelines, install the detector within ±45°of the horizontal centerline. Try to choose the horizontal centerline position.

3. When install the ultrasonic flow meter, need to input these parameters: pipe material,pipe wall thickness and pipe diameter. Fulid type, whether it contains impurities,bubbles, and whether the tube is full.

Transducers installation

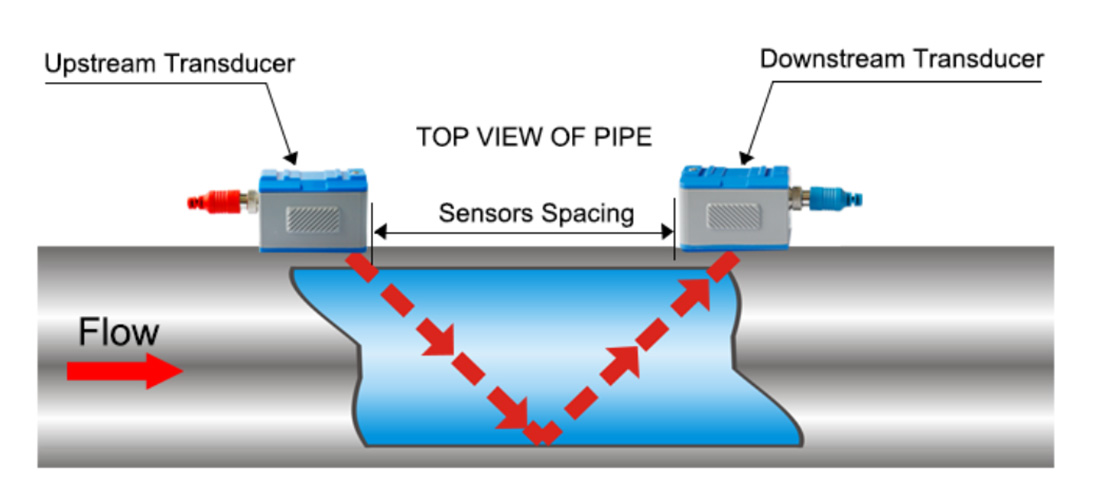

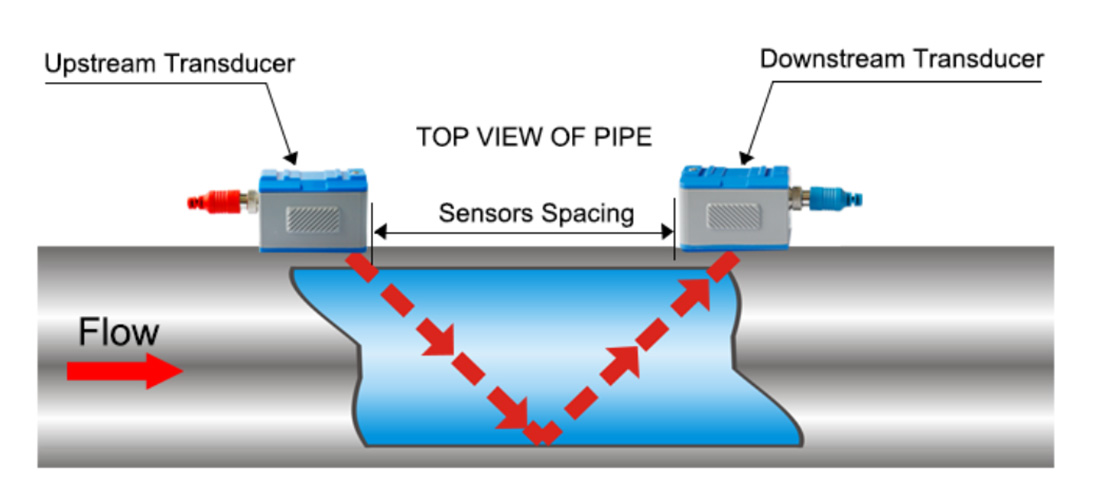

1. V-method Installation

V-method installation is the most widely used mode for daily measurement with pipe inner diameters ranging from DN15mm ~ DN200mm. It is also called reflective mode or method.

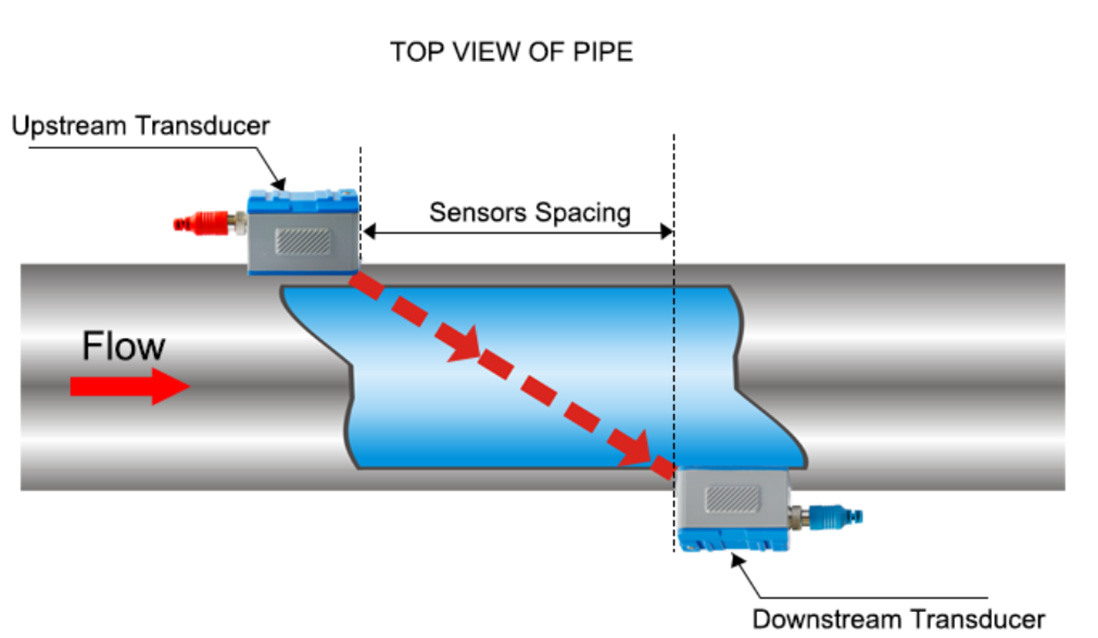

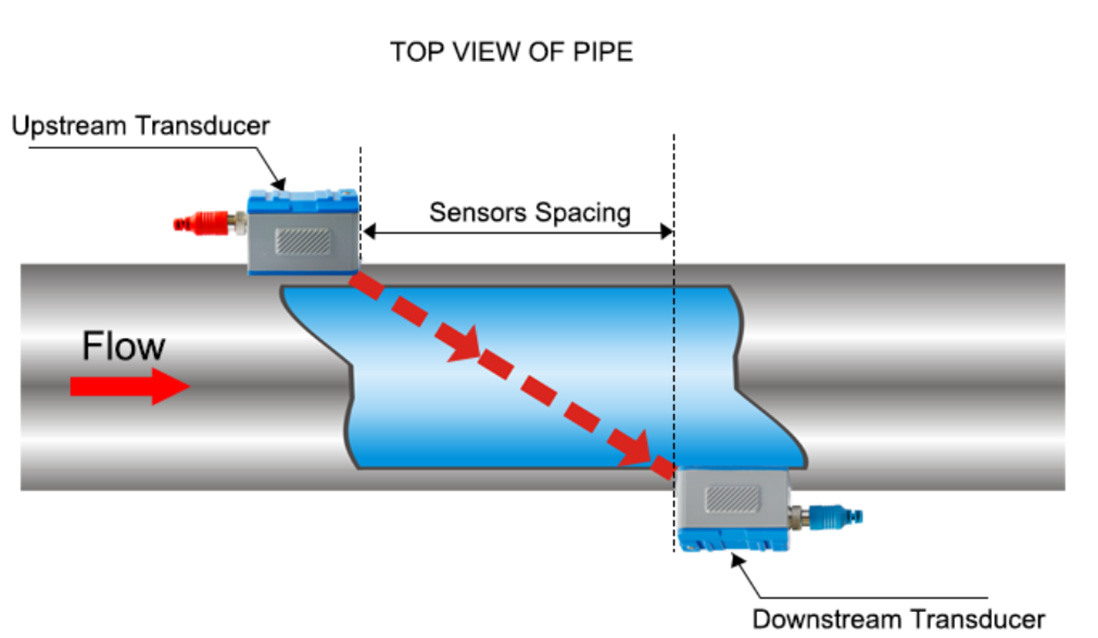

2. Z-method Installation

2. Z-method Installation

Z-method is commonly used when the pipe diameter is above DN300mm.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)