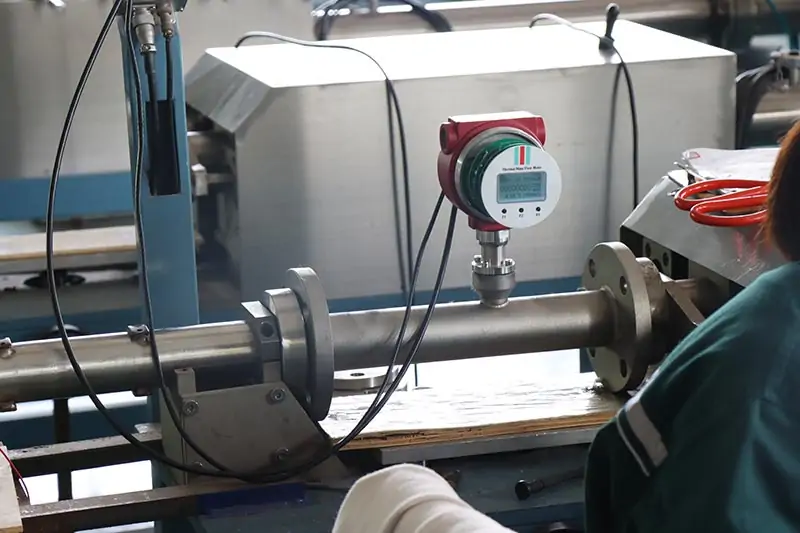

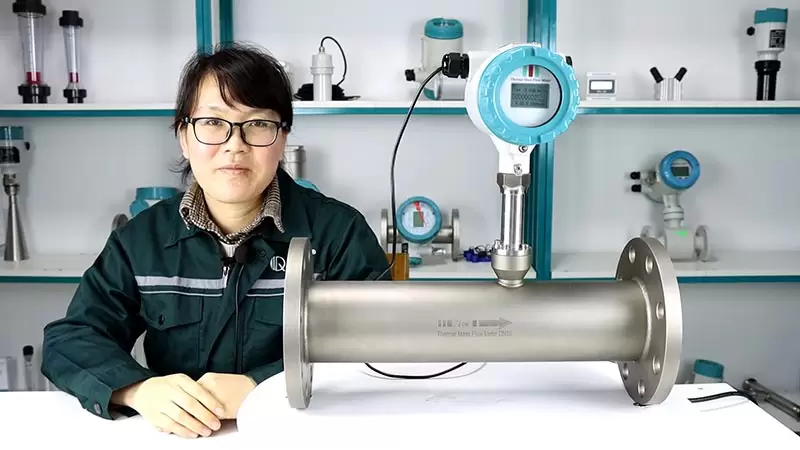

Thermal mass flow meter for gas

Compressed air thermal gas mass flow meter is very intelligent gas flow meter and can display Nm3 and Kg unit at same time.

And thermal gas mass flow meter be adopted dual power supply,user can easy to choose the poer spurce.

Thermal flow meter measure gas mass flow in various processes and offer distinct advantages, such as repeatability, low maintenance, and operating over a wide flow range. Here we discuss the meter¡¯s fundamentals, the working principle of thermal mass flow measurement, and the two approaches to measuring heat dissipation.

Introduction

Flange thermal gas mass flow meter is one of kind mass flow meter which is popular in industrial applications is the way they are designed and built. The feature is no moving parts, nearly unobstructed straight through flow path, require no temperature or pressure corrections and retain accuracy over a wide range of flow rates. Straight pipe runs can be reduced by using dual-plate flow conditioning elements and installation is very simple with minimal pipe intrusions.

Flange thermal gas mass flow meter size from DN10~DN2000mm

|

|

|

https://www.qtmeters.com/products/thermal-mass-flow-meter/

Advantages

Flange thermal gas mass flow meter advantanges :

(1)Wide range ratio 1000:1;

(2)Large diameter, low flow rate, negligible pressure loss;

(3)Direct mass flow measurement without temperature and pressure compensation;

(4)Very sensitive for low flow rate measurement;

(5)Easy to design and select, easy to install and use;

(6)Suitable for all kinds of single or mixed gas flow measurement Could measure gas with flow velocity from 100Nm/s to 0.1Nm/s, which can be used for gas leak detection;

(7) The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on the measurement accuracy. It has good seismic performance and high measurement reliability;

(8) No pressure loss or very small pressure loss.

(9) When measuring the gas flow, it is often expressed in the volume flow unit under the standard state, and the medium temperature/pressure change hardly affects the measured value. If the density is constant in the standard state (that is, the composition is unchanged), it is similar to a mass flow meter;

(10) Support multiple communication methods, such as RS485 communication, MODBUS protocol, etc., which can realize factory automation and integration

Technical Data

Table 1: Flange Thermal Gas Mass Flow Meter Parameter

| Measuring Medium | Various of Gas (Except acetylene) |

| Pipe Size | (Insert connection) DN50-DN2000mm ,In-line connection(DN10-DN2000mm) |

| Velocity | 0.1-100Nm/s |

| Accuracy | +/-1~2.5% |

| Working Temperature | Sensor:-40~+220 degC Transmitter:-20~+45 degC |

| Working Pressure | Insertion Sensor:medium pressure ≤1.6Mpa

Flanged Sensor:medium pressure ≤4.0Mpa Special pressure please double check |

| Power Supply | Compact type: 24VDC or 220VAC, Power consumption ≤18W

Remote type:220VAC,Power consumption ≤19W |

| Response Time | 1s |

| Output | 4-20mA(optoelectronic isolation,maximum load 500Ω),Pulse RS485(optoelectronic isolation) and HART |

| Alarm Output | 1-2 line Relay, Normally Open state, 10A/220V/AC or 5A/30V/DC |

| Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

| Construction | Compact and Remote |

| Pipe Material | Carbon Steel, Stainless Steel,Plastic etc. |

| Display | 4 lines LCD Mass flow, Volume flow in standard condition, Flow totalizer, Date and Time, Working time, and Velocity, etc. |

| Protection | IP65 |

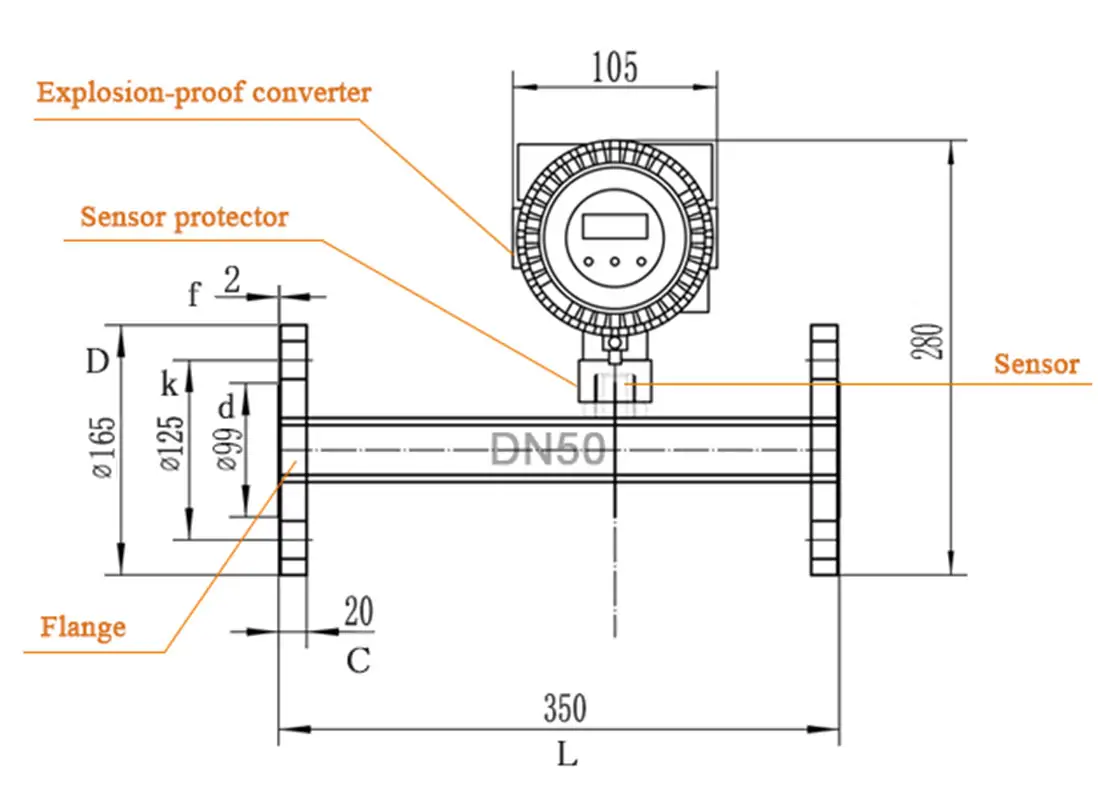

Table 2: Flange Thermal Gas Mass Flow Meter Sizing

| Nominal Diameter | Flange outer diameter | Center hole | Bolt hole | Screw Threads | Sealing face | Flange thickness | Installation length | |

| DN | D | k | n x L | d | f | C | L | |

| 15 | 95 | 65 | 4×14 | M12 | 46 | 2 | 14 | 280 |

| 20 | 105 | 75 | 4×14 | M12 | 56 | 2 | 16 | 280 |

| 25 | 115 | 85 | 4×14 | M12 | 65 | 2 | 16 | 280 |

| 32 | 140 | 100 | 4×18 | M16 | 76 | 2 | 18 | 350 |

| 40 | 150 | 110 | 4×18 | M16 | 84 | 2 | 18 | 350 |

| 50 | 165 | 125 | 4×18 | M16 | 99 | 2 | 20 | 350 |

| 65 | 185 | 145 | 4×18 | M16 | 118 | 2 | 20 | 400 |

| 80 | 200 | 160 | 8×18 | M16 | 132 | 2 | 20 | 400 |

| 100 | 220 | 180 | 8×18 | M16 | 156 | 2 | 22 | 500 |

Table 3: Common Use Gas Maximum Range

| Caliber

( mm ) |

Air | Nitrogen ( N2 ) | Oxygen ( O2 ) | Hydrogen ( H2 ) |

| 15 | 65 | 65 | 32 | 10 |

| 25 | 175 | 175 | 89 | 28 |

| 32 | 290 | 290 | 144 | 45 |

| 40 | 450 | 450 | 226 | 70 |

| 50 | 700 | 700 | 352 | 110 |

| 65 | 1200 | 1200 | 600 | 185 |

| 80 | 1800 | 1800 | 900 | 280 |

| 100 | 2800 | 2800 | 1420 | 470 |

| 125 | 4400 | 4400 | 2210 | 700 |

| 150 | 6300 | 6300 | 3200 | 940 |

| 200 | 10000 | 10000 | 5650 | 1880 |

| 250 | 17000 | 17000 | 8830 | 2820 |

| 300 | 25000 | 25000 | 12720 | 4060 |

| 350 | 45000 | 45000 | 22608 | 5600 |

| 400 | 70000 | 70000 | 35325 | 7200 |

| 450 | 100000 | 100000 | 50638 | 9200 |

| 500 | 135000 | 135000 | 69240 | 11280 |

| 600 | 180000 | 180000 | 90432 | 16300 |

| 700 | 220000 | 220000 | 114500 | 22100 |

| 800 | 280000 | 280000 | 141300 | 29000 |

| 900 | 400000 | 400000 | 203480 | 36500 |

| 1000 | 600000 | 600000 | 318000 | 45000 |

| 2000 | 700000 | 700000 | 565200 | 18500 |