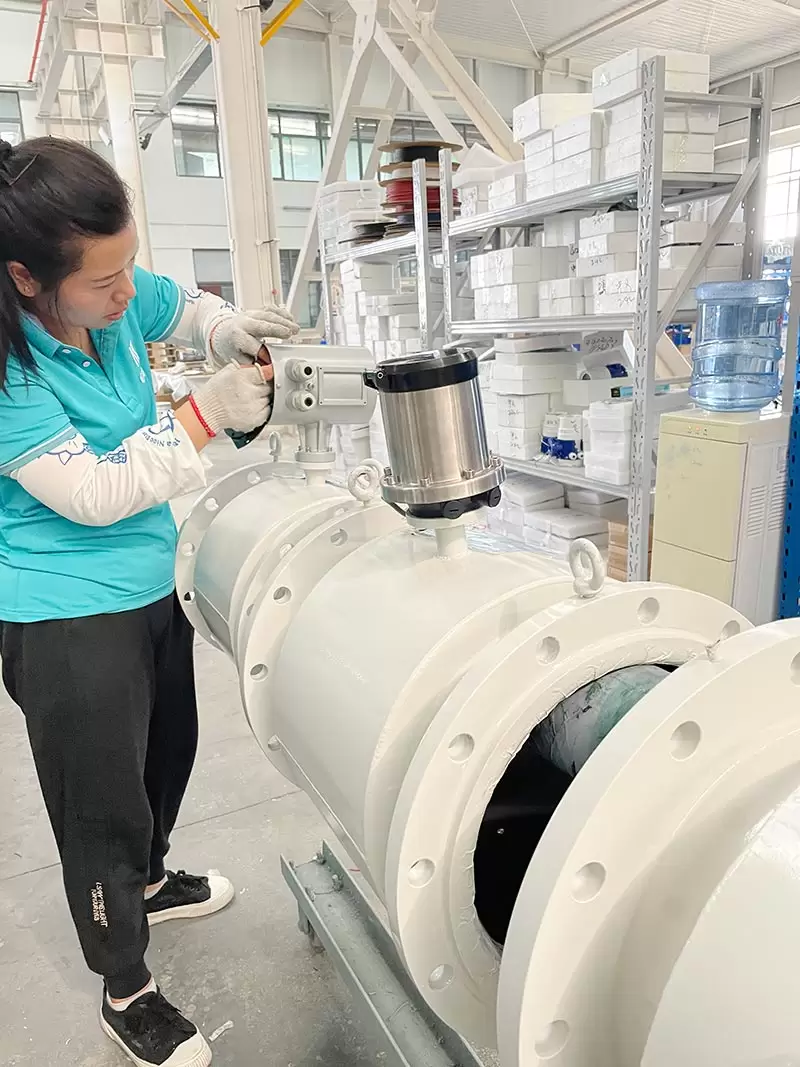

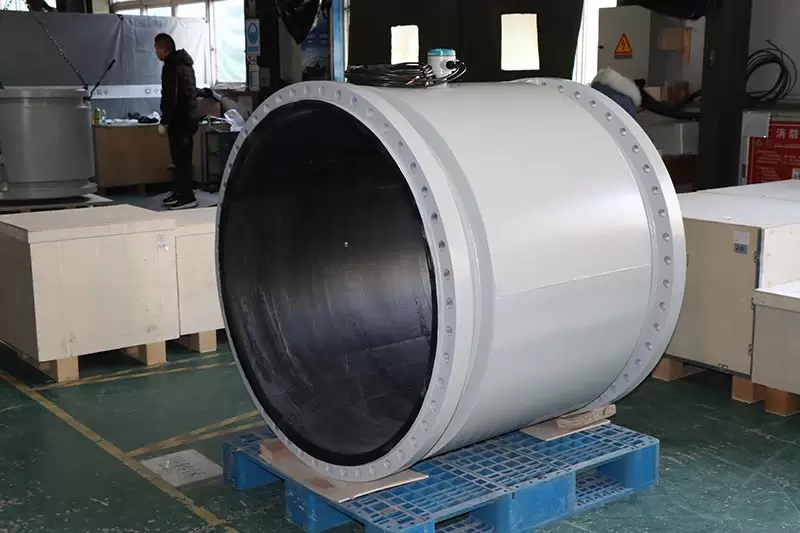

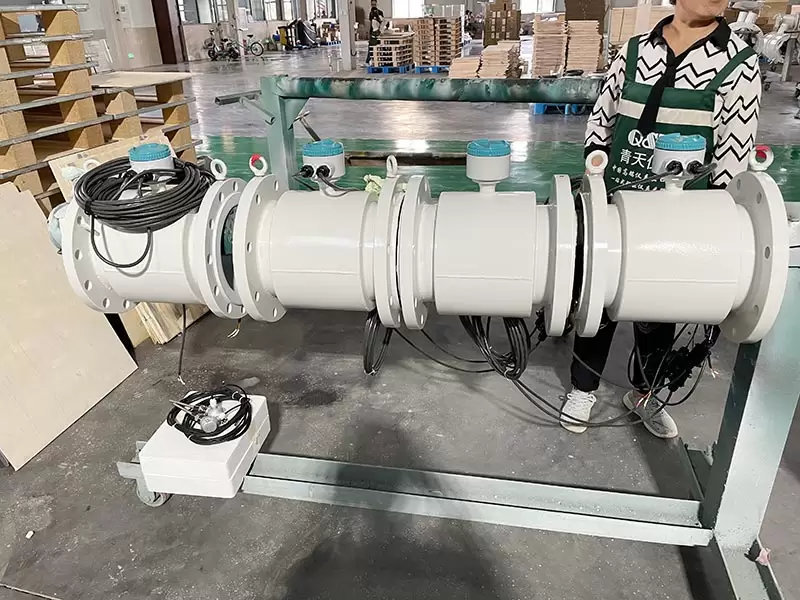

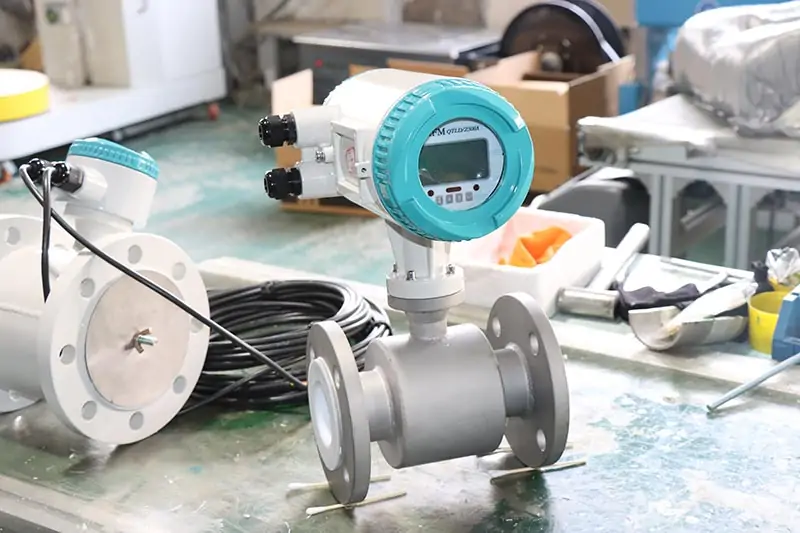

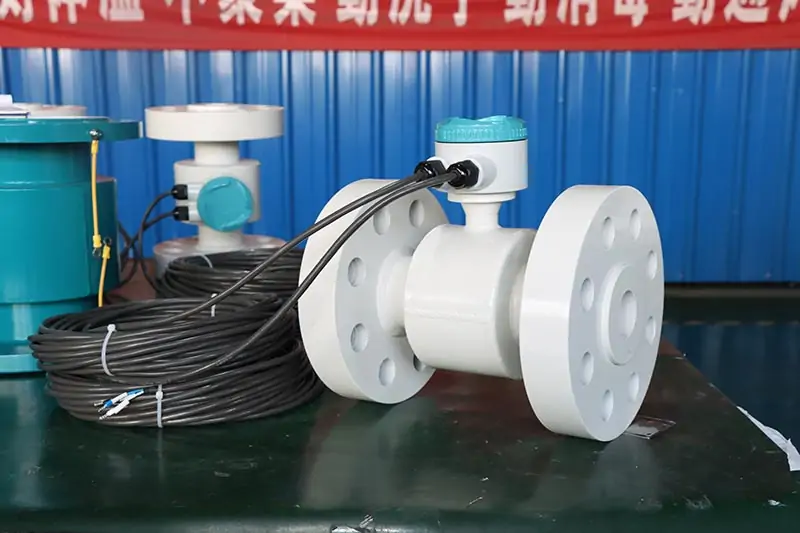

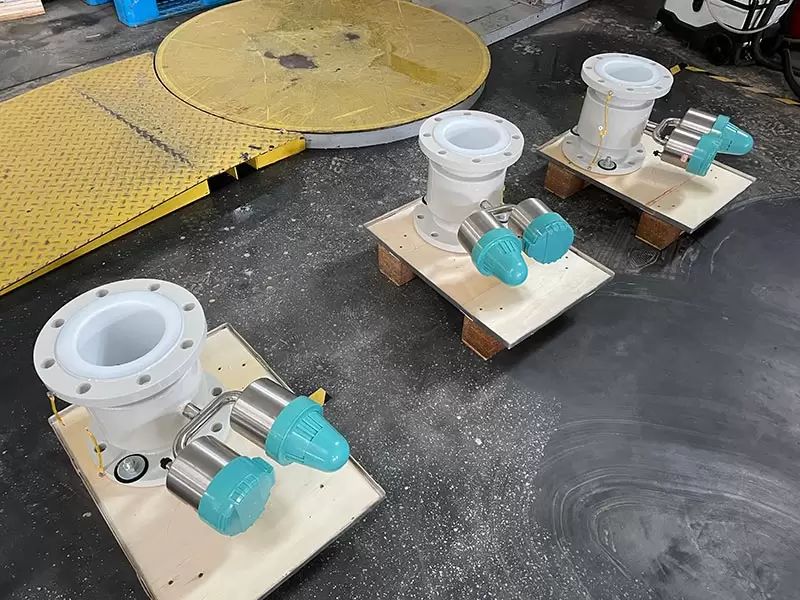

Magnetic Flow Meter Clamp Electromagnetic Flowmeter Modbus Water Flow Meter

electromagnetic flowmeter can be used to measure the volume flow of conductive fluid in a closed pipeline. It is widely applied in the flow measurement and control in the fields of chemical and petroleum industry, metallurgy industry, water and wastewater, agriculture and irrigation, paper making, food and beverage industry and pharmaceutical industry, etc.

When the conductive fluid flows through the measuring tube of the sensor, the voltage signal in direct proportion to the average flow velocity of the fluid will be inducted on the electrodes. The signal is amplified and treated by the transmitter to realize various display functions.

Size: 1/8″-120″

Accuracy: ±0.5%

Electrode: SUS316L, Hastelloy B, Hastelloy C

Structure: compact, remote

Liner: PTFE, PFA, Polyurethane, Neoprene, Hard Rubber, Ceramic

Output Signal: 4~20 mA, Pulse

Communication: RS485, HART, PROFIBUS

Protection Grade: IP65 std, IP68 optional for remote

Velocity: 0.1~15 m/s

Conductivity: > 5 μS/cm, demineralized water > 20 µS/cm

Power supply: 85~250 VAC, 20V~36VDC, 3.6V lithium battery

Size: DN3-DN3000

Sensor material: carbon steel (std), SS304 / SS316 (optional)

Flange: ANSI, DIN, JIS, etc.