Home » Flow Meter » Electromagnetic Flow Meter » Integrated type built-in data logger magnetic flowmeter

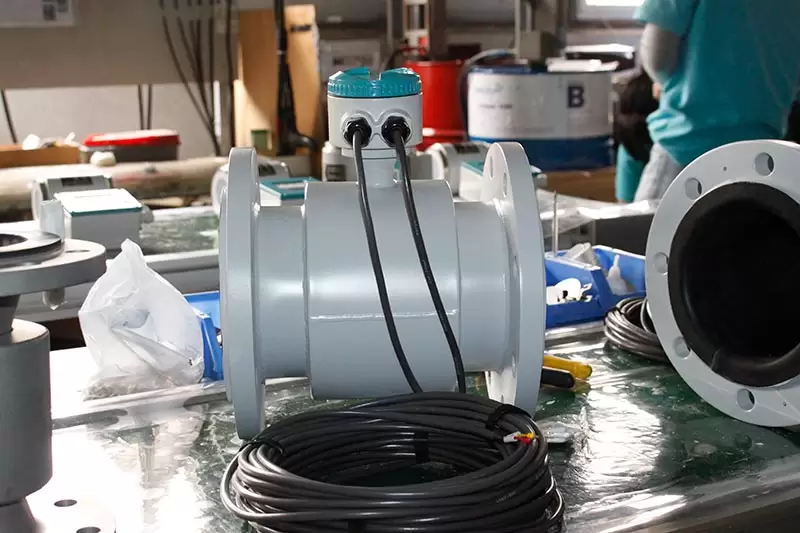

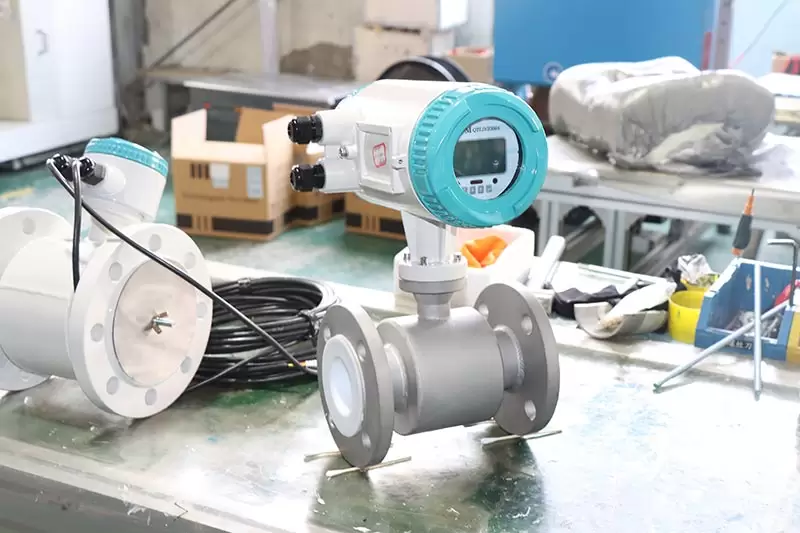

Integrated type built-in data logger magnetic flowmeter

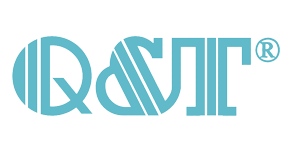

electromagnetic flowmeters are calibrated 5 points by Mass Method liquid calibration equipment, all test bench are stainless steel., magnetic flow meter is calibrated on ¡À0.2% accuracy test bench, Liquid flow meter is widely used in Sewage Treatment Plant Water Supply project and Steel & Aluminum Industries, Chemical & Fertilizer Industries.

Conductivity: > 5 ¦ÌS/cm, demineralized water > 20 ¦ÌS/cm

Size: DN3-DN3000

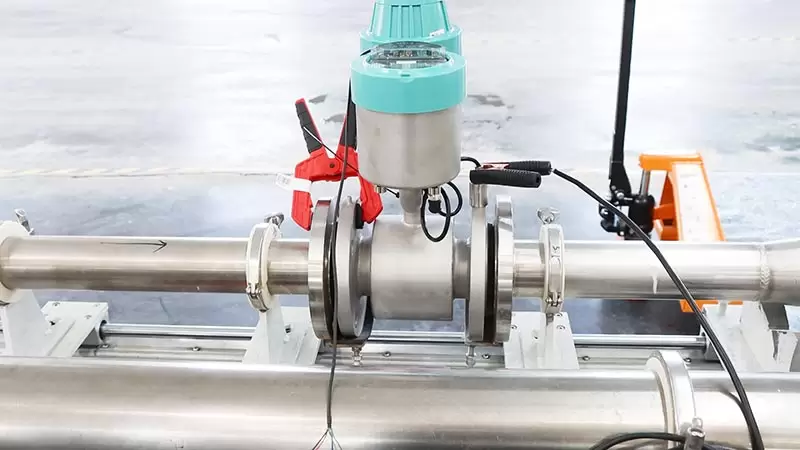

Sensor material: carbon steel (std), SS304 / SS316 (optional)

Measuring tube: SS304

Function: High and low alarm, exciting alarm, empty pipe alarm, self-diagnosis

Contact US

Get Price

Share:

Content

Inquiry

More Electromagnetic Flow Meter