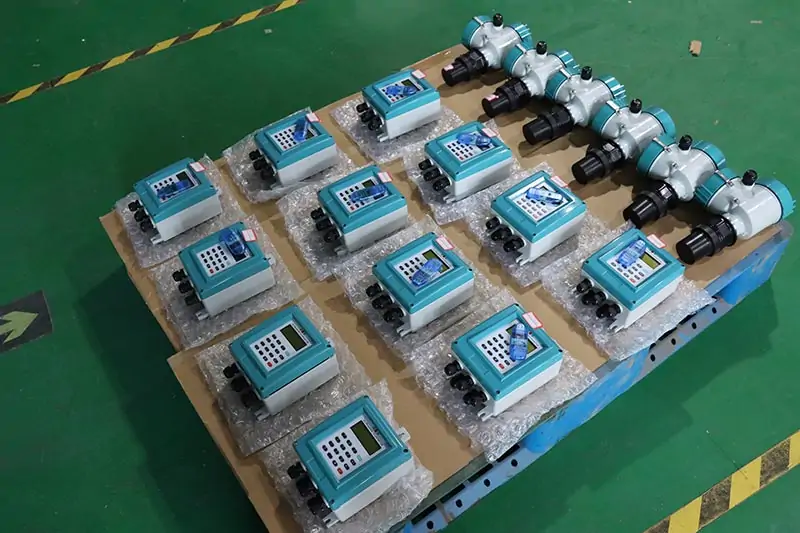

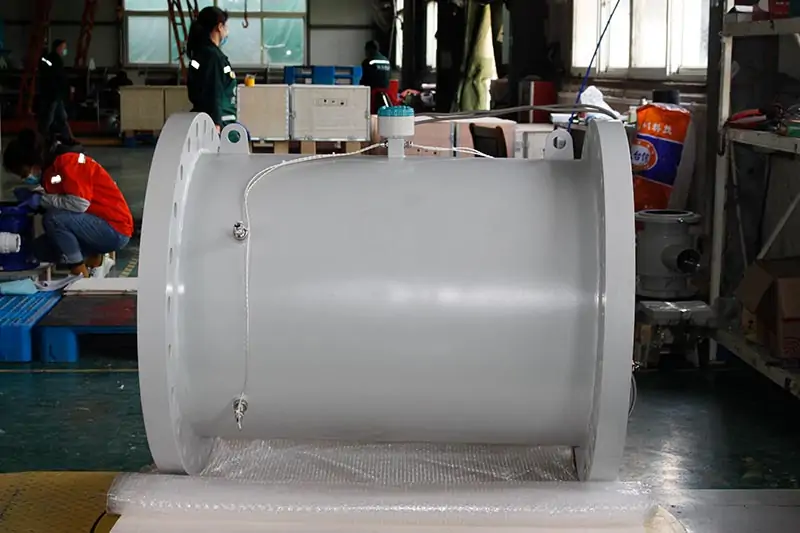

DN100 ultrasonic flow meter with 4-20mA output

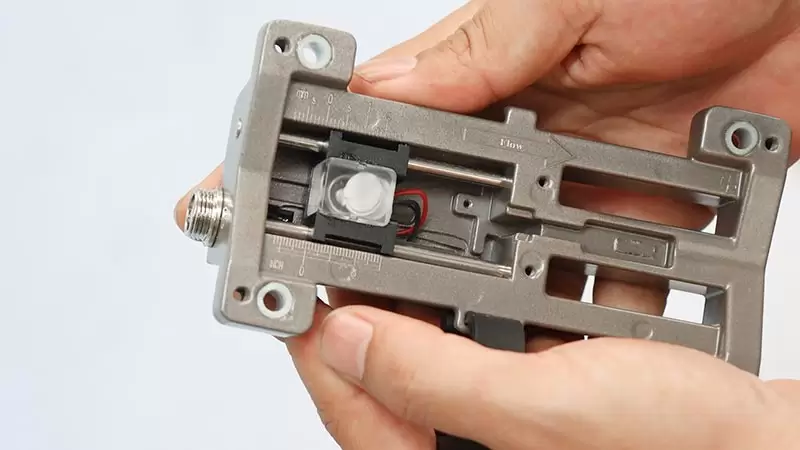

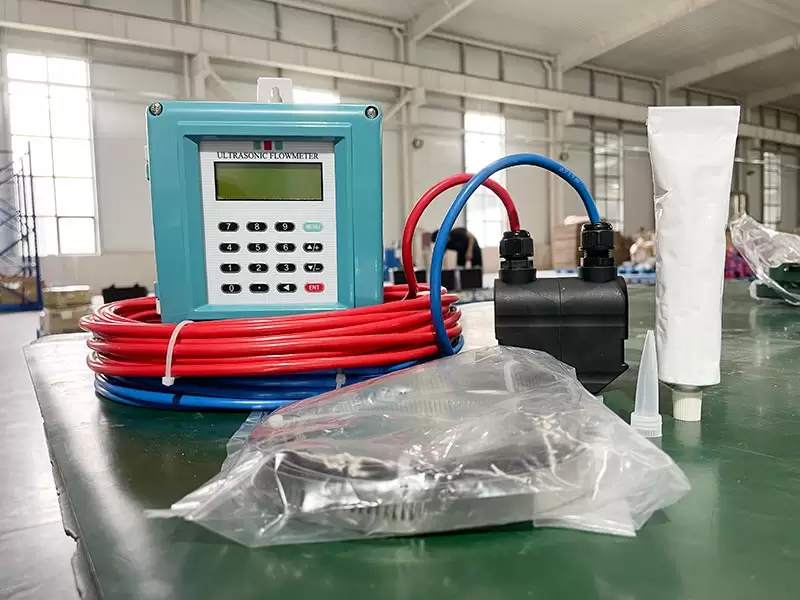

Pipeline ultraosnic flow meter directly contact the liquid and make the measuring accuracy better than clamp on ultrasonic flowmeter.And installation easy,don’t need calculate the sensor installation distance and cover the coupling agent in the pipe,so this meter can collect the signal very well.

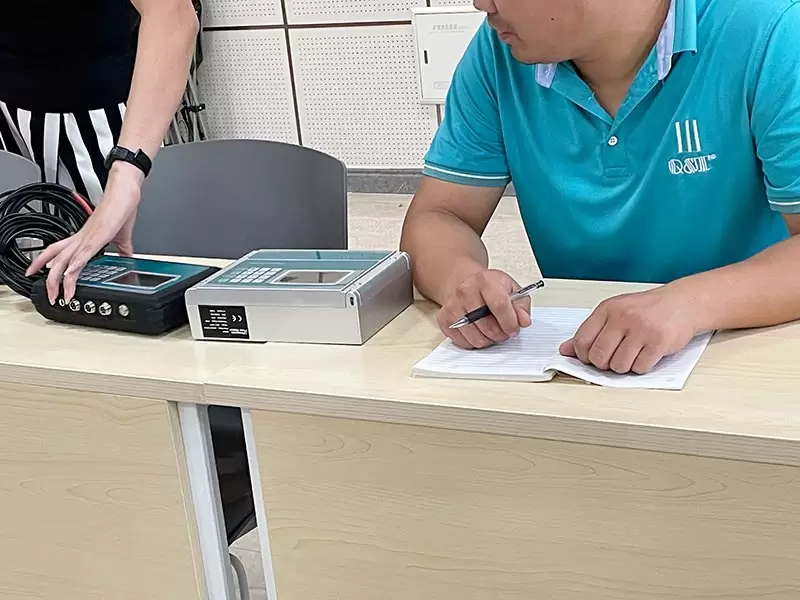

Introduction

Flange ultraosnic flow meter is one kind of economy liquid flow meter which mainly measure various of pure liquid,such as:Clean water,Sea water,Dringking water,River water,Alcohol etc.

And it is suitable for continuously measuring flow and heat of clean and uniform liquids without large concentration suspended particles or gases industrial environment.

|

|

|

|

|

Advantages

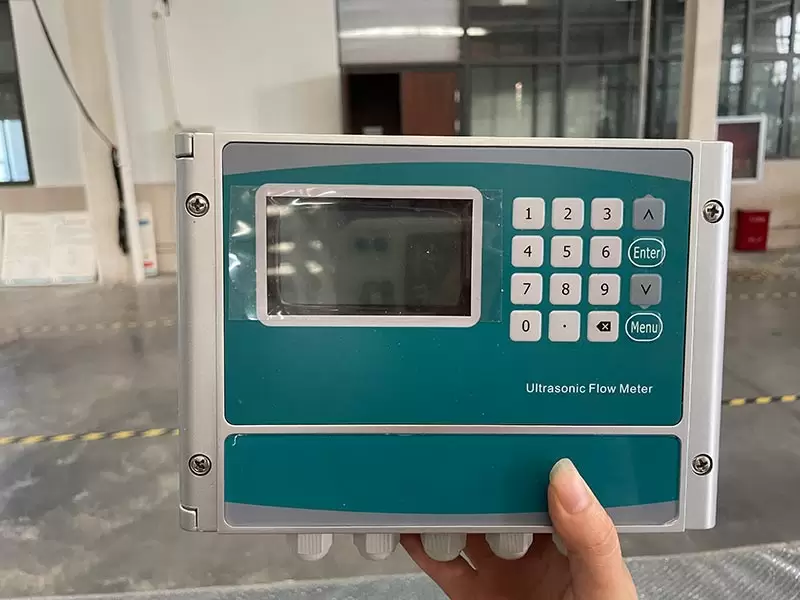

Accuracy better than ±1.0%; High reliability, high performance, low price

Bi-directional flow measurement; No moving parts, no wear, no pressure loss,Maintenance-free

Measuring conductivity liquid and Non-conductivity liquid; Display instantaneous flow,Total flow,Heat,Positive flow,Negative flow

High-precision machined pipe sections, the sensor is installed before leaving the factory to ensure high measurement accuracy

Application

Inline ultrasonic flow meter could connect temperature sensor to become one calorimeter and widely be used in Food industry, Oil & Gas industry, Chemical industry,Water treatment industry, Trade settlement,Power industry

Technical Data

Table 1 : Integral Display Flange Ultrasonic Flow Meter Main Performances Parameters

| Description | Specifications |

| Size | DN15~DN6000 |

| Accuracy | Better than ±1.0% |

| Velocity range | 0~±10m/s |

| Liquid temperature | 0~160℃ |

| Liquid Type | Water, sea water, waste water, alcohol, beer, various kinds of oil etc which can conduct ultrasound single uniform liquid |

| Pipe material | Steel, stainless steel, cast iron, copper, PVC, aluminum, FRP etc, all kinds Of dense pipeline, can be liner inside |

| Output signal | 1 channel 4-20mA output, inpedence 0-1K ; 1 channel OCT pulse output, pulse width 6-1000ms, (default is 200ms); 1 channel relay output |

| Input Signal | 4-20mA input Connect with three wire PT100, can achieve heat measurement |

| Communication | RS485 MODBUS RTU |

| Power supply | DC8-36V or AC85-264V |

| Protection | IP65 |

| Power Consumption | 1.5W |

Table 2 : Water temperature and sound speed table

| Temperature(℃ ) | Sound speed (m/s) | Temperature(℃) | Sound speed (m/s) |

| 0 | 1403 | 50 | 1541 |

| 5 | 1427 | 55 | 1546.5 |

| 10 | 1447 | 60 | 1552 |

| 15 | 1464 | 65 | 1553.5 |

| 20 | 1481 | 70 | 1555 |

| 25 | 1494 | 75 | 1555 |

| 30 | 1507 | 80 | 1555 |

| 35 | 1516.5 | 85 | 1552.5 |

| 40 | 1526 | 90 | 1550 |

| 45 | 1533.5 | 95 | 1547 |

| 100 | 1543 |

Installation

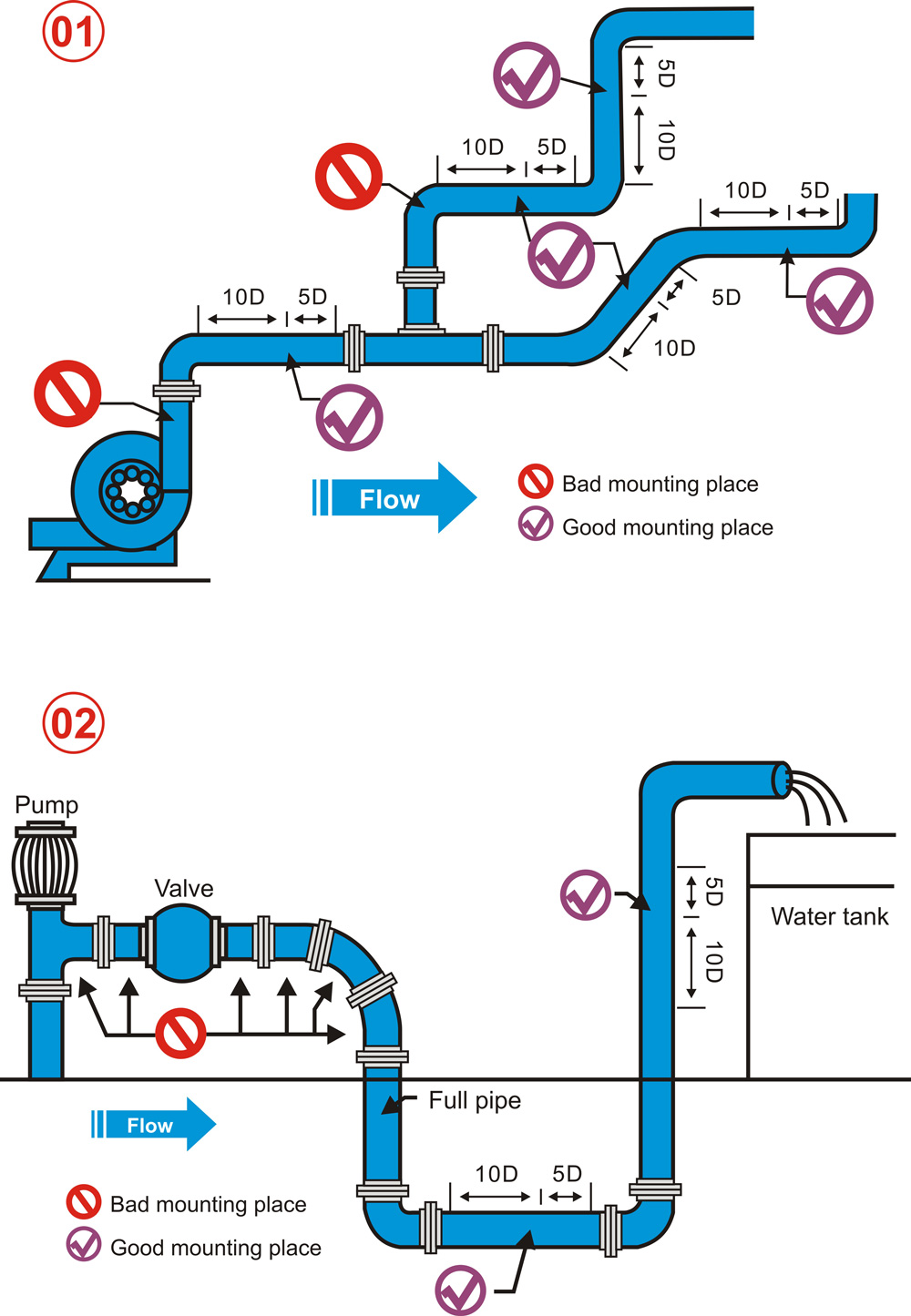

Integral Display Flange Ultrasonic Flow Meter Installation Requirement

Generally, the following principles should be followed:

- To select a pipe section filled with fluid, such as a vertical part of the pipeline or a horizontal pipe section filled with fluid.

- The measuring point should be 10 times the diameter from the upstream and the straight pipe section within 5 times the diameter from the downstream, and the distance from the valve outlet should be as far as possible.

- Ensure the temperature at the measuring point is within the working range.

- Fully consider the fouling condition of the inner wall of the pipe, and try to select a non-scaling pipe section for measurement. When it cannot be satisfied, fouling should be considered as a lining for better measurement accuracy.

- Select pipe sections with uniform and dense pipes that are easy for ultrasonic transmission.

- Please refer to the two examples on the right for the selection of measuring points.